Panthawi ya hardfacing process, ming'alu nthawi zambiri imayambitsa mavuto monga kukonzanso komanso kubwerera kwa kasitomala. Maonekedwe olimba amasiyana ndi kuwotcherera kwapang'onopang'ono, ndipo momwe ming'alu imawonera komanso kuyang'ana kwake ndi kosiyana. Nkhaniyi ikuwunika ndikukambirana momwe ming'alu imawonekera popanga mawonekedwe olimba osamva kuvala.

1. Kutsimikiza kwa ming'alu

Pakalipano, m'nyumba komanso padziko lonse lapansi, palibe muyezo wamba wa ming'alu yomwe imayambitsidwa ndi kuvala kolimba. Chifukwa chachikulu ndi chakuti pali mitundu yambiri yogwirira ntchito pazovala zolimba za pamwamba, ndipo n'zovuta kufotokozera njira zosiyanasiyana zogwiritsira ntchito zowonongeka pansi pazimenezo. Komabe, malinga ndi zomwe zachitika pakugwiritsa ntchito zida zowotcherera zolimba zolimba m'magawo osiyanasiyana, ma degree angapo a crack amatha kusanjidwa mozama, komanso momwe amavomerezera m'mafakitale osiyanasiyana:

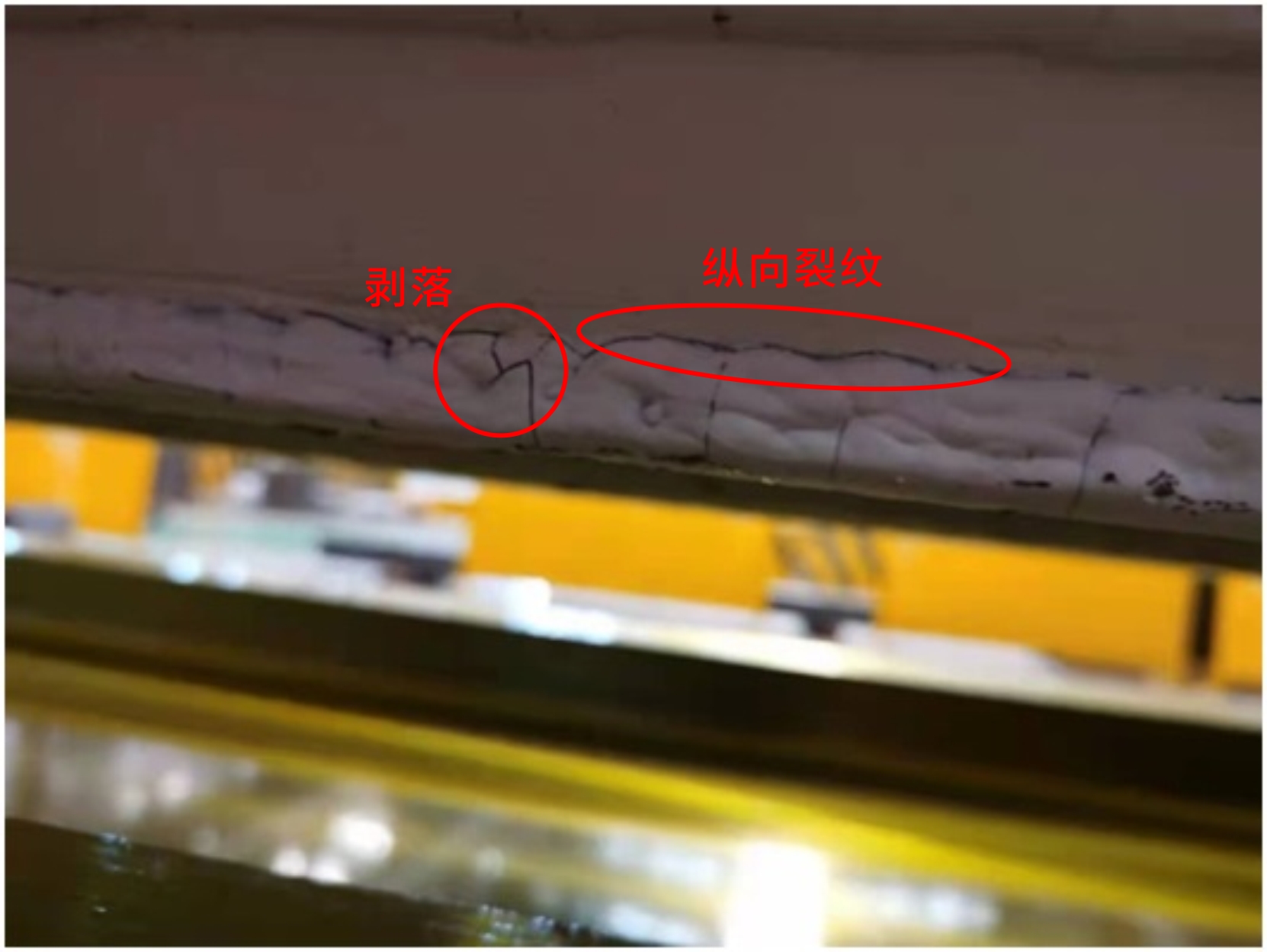

1. Mayendedwe a ng'anjoyo ndi ofanana ndi mkanda wowotcherera (kung'amba kotalika), kung'amba kosalekeza, kung'ambika mpaka kuzitsulo zoyambira, spalling.

Malingana ngati mng'alu womwe watchulidwa pamwambapa wakwaniritsidwa, pali chiopsezo kuti chigawo chonsecho chidzagwa. Kwenikweni, ziribe kanthu kuti ntchitoyo ndi yotani, sizovomerezeka ndipo imatha kukonzedwanso ndikugulitsidwanso.

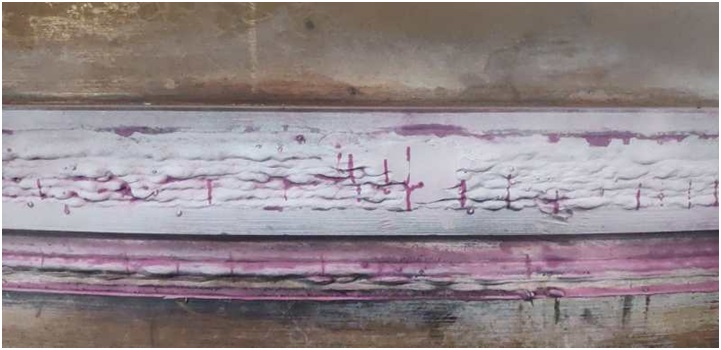

2. Pali ming'alu yopingasa ndi kutha

Kwa zogwirira ntchito zomwe zimalumikizana ndi zinthu zolimba monga ore, mchenga, ndi migodi ya malasha, kulimba kumafunika kukhala kokwezeka (HRC 60 kapena kupitilira apo), ndipo zida zowotcherera za chromium zambiri zimagwiritsidwa ntchito powotcherera. Makhiristo a chromium carbide omwe amapangidwa mu weld bead adzapangidwa chifukwa cha kutulutsa nkhawa. Ming'alu ndi zovomerezeka malinga ngati ng'anjo ya ng'anjo imakhala yokhazikika kwa weld bead (yopingasa) ndipo imasiya. Komabe, kuchuluka kwa ming'alu kudzagwiritsidwabe ntchito ngati chifaniziro chofananiza zabwino ndi zoyipa zazowotcherera kapena njira zowonekera.

3. Palibe crack weld bead

Kwa zida zogwirira ntchito monga ma flanges, mavavu, ndi mapaipi, pomwe zinthu zazikuluzikulu zolumikizana ndi mpweya ndi zakumwa, zofunikira za ming'alu ya weld bead ndizosamala, ndipo nthawi zambiri zimafunikira kuti mawonekedwe a weld bead asakhale ndi ming'alu.

Mng'alu pang'ono pamwamba pa zogwirira ntchito monga ma flanges ndi ma valve ayenera kukonzedwa kapena kukonzedwanso.

Gwiritsani ntchito zida zathu zowotcherera zapadera za GFH-D507Mo za kampani yathu kuti ziwonekere, palibe ming'alu pamtunda.

2. Zomwe zimachititsa kuti ming'alu yapamtunda ikhale yolimba

Pali zinthu zambiri zomwe zimayambitsa ming'alu. Kwa kuwotcherera kolimba pamwamba pamadzi osamva, kumatha kugawidwa m'ming'alu yotentha yomwe imapezeka pambuyo pa chiphaso choyamba kapena chachiwiri, ndi ming'alu yozizira yomwe imawonekera pambuyo pa chiphaso chachiwiri kapena ngakhale kuwotcherera.

Hot crack:

Panthawi yowotcherera, chitsulo mumsoko wowotcherera ndi malo okhudzidwa ndi kutentha amazizira kumalo otentha kwambiri pafupi ndi mzere wa solidus kuti apange ming'alu.

Cold crack:

Ming'alu yomwe imapangidwa pa kutentha pansi pa solidus (pafupifupi kutentha kwa martensitic kusintha kwachitsulo) makamaka imapezeka muzitsulo zapakati-carbon ndi zitsulo zotsika kwambiri zotsika kwambiri ndi zitsulo zapakatikati.

Monga momwe dzinalo likusonyezera, zinthu zolimba zolimba zimadziwika chifukwa cha kuuma kwawo kwakukulu. Komabe, kufunafuna kuuma kwamakina kumabweretsanso kuchepa kwa pulasitiki, ndiko kuti, kuwonjezeka kwa brittleness. Nthawi zambiri, kuyang'ana pamwamba pa HRC60 sikulabadira kwambiri ming'alu yotentha yomwe imapangidwa panthawi yowotcherera. Komabe, kuwotcherera molimba ndi kuuma pakati pa HRC40-60, ngati pali kufunikira kwa ming'alu, ming'alu ya intergranular mu njira yowotcherera kapena ming'alu yamitundu yosiyanasiyana yomwe imayamba chifukwa cha mkanda wowotcherera chapamwamba kudera lomwe lakhudzidwa ndi kutentha. mikanda ndi zovuta kwambiri.

Ngakhale ngati vuto la ming'alu yotentha likuyendetsedwa bwino, chiwopsezo cha ming'alu yozizira chidzayang'anizanabe pambuyo pa kuwotcherera, makamaka zinthu zowonongeka kwambiri monga hard surface weld bead, zomwe zimakhudzidwa kwambiri ndi ming'alu yozizira. Kusweka kwakukulu kumachitika makamaka chifukwa cha ming'alu yozizira

3. Zinthu zofunika zomwe zimakhudza ming'alu yosamva kuvala pamalo olimba ndi njira zopewera ming'alu

Zinthu zofunika zomwe zingathe kufufuzidwa pamene ming'alu ikuchitika muzitsulo zolimba zovalira ndi izi, ndipo njira zofananira zimaperekedwa pa chinthu chilichonse kuti chichepetse chiopsezo cha ming'alu:

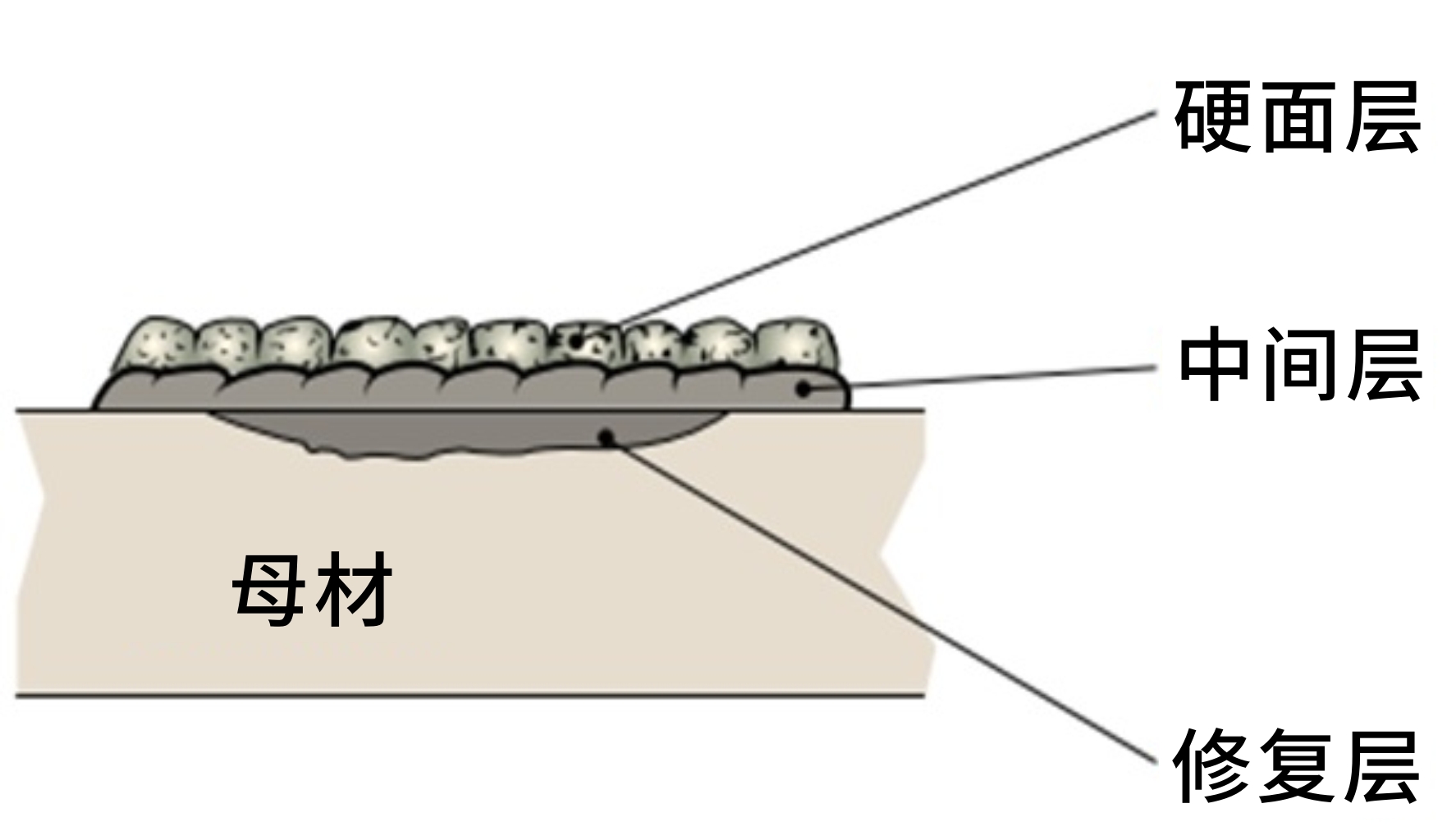

1. Zida zoyambira

Mphamvu ya chitsulo choyambira pamalo olimba osamva kuvala ndikofunika kwambiri, makamaka kwa zida zogwirira ntchito zokhala ndi magawo awiri azitsulo zowotcherera. The zikuchokera zitsulo m'munsi zimakhudza mwachindunji katundu weld bead. Kusankha kwazinthu ndi tsatanetsatane wofunikira kuwunikira musanayambe ntchito. Mwachitsanzo, ngati chopangira valavu chokhala ndi chandamale cholimba cha HRC30 chikuwonekera ndi chitsulo chosungunula, tikulimbikitsidwa kugwiritsa ntchito chowotcherera chokhala ndi kulimba pang'ono, kapena kuwonjezera wosanjikiza wapakati wachitsulo chosapanga dzimbiri, kuti pewani kaboni zomwe zili m'munsi kuti zisawonjezere chiopsezo cha ming'alu ya weld.

Onjezani wosanjikiza wapakatikati pazinthu zoyambira kuti muchepetse chiopsezo chosweka

2. kuwotcherera consumables

Kwa ndondomeko yomwe imasowa ming'alu, zowonjezera zowonjezera carbon ndi high-chromium sizoyenera. Ndi bwino kugwiritsa ntchito martensitic dongosolo kuwotcherera consumables, monga wathu GFH-58. Imatha kuwotcherera pamalo opanda ming'alu pamene kulimba kwake kuli kokwera kwambiri mpaka HRC58~60, makamaka koyenera kumalo ogwirira ntchito omwe sali olinganizidwa bwino omwe amapsa kwambiri ndi dothi ndi miyala.

3. Kuyika kwa kutentha

Kumanga pa malo kumakonda kugwiritsa ntchito mphamvu zamakono ndi magetsi chifukwa cha kutsindika pakuchita bwino, koma kuchepetsa pang'onopang'ono kwamakono ndi magetsi kungathandizenso kuchepetsa kuchitika kwa ming'alu ya kutentha.

4. Kuwongolera kutentha

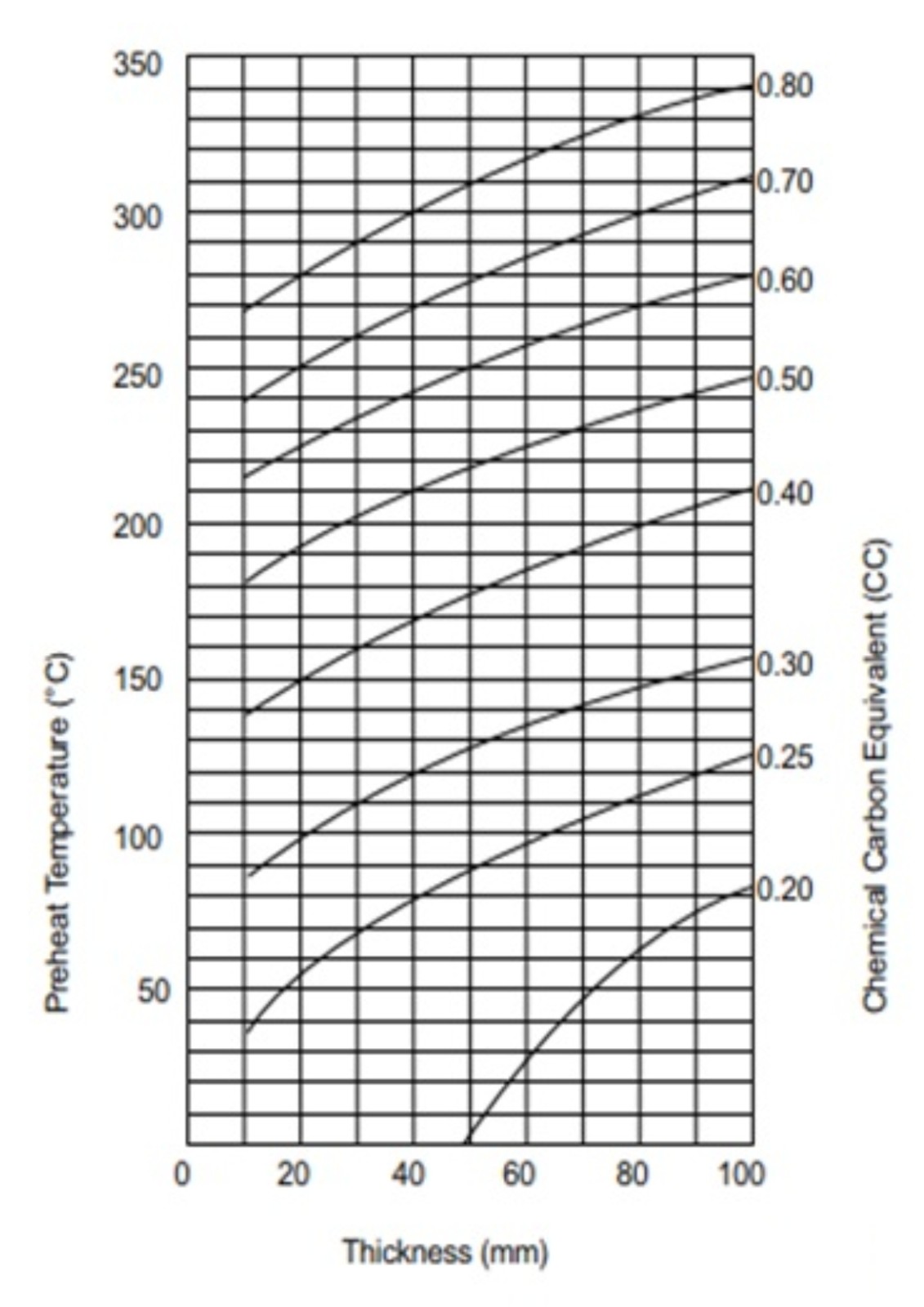

Mipikisano wosanjikiza ndi Mipikisano chiphaso hardfacing kuwotcherera akhoza kuonedwa ngati ndondomeko mosalekeza Kutentha, kuzirala ndi reheating aliyense chiphaso, kotero kulamulira kutentha n'kofunika kwambiri, kuchokera preheating pamaso kuwotcherera podutsa kutentha pa surfacing Control, ndipo ngakhale ndondomeko yozizira pambuyo. kuwotcherera, kumafuna chisamaliro chachikulu.

Kutentha kwa preheating ndi kutentha kwapang'onopang'ono kumagwirizana kwambiri ndi mpweya wa gawo lapansi. Gawo lapansi pano limaphatikizapo zinthu zoyambira kapena zosanjikiza zapakatikati, ndi pansi pazovuta. Nthawi zambiri, chifukwa cha kaboni wazitsulo zolimba zomwe zimayikidwa ngati zili pamwamba, tikulimbikitsidwa kusunga kutentha kwa msewu kupitilira madigiri 200. Komabe, pakugwira ntchito kwenikweni, chifukwa cha kutalika kwa mkanda wowotcherera, mbali yakutsogolo ya weld bead idakhazikika pakutha kwa chiphaso chimodzi, ndipo chiphaso chachiwiri chidzatulutsa mosavuta ming'alu m'malo omwe amakhudzidwa ndi kutentha kwa gawo lapansi. . Chifukwa chake, pakalibe zida zoyenera zosungira kutentha kwa njira kapena kutentha musanayambe kuwotcherera, tikulimbikitsidwa kugwiritsa ntchito magawo angapo, ma welds amfupi, ndi kuwotcherera mosalekeza m'gawo lomwelo kuti musunge kutentha kwanjira.

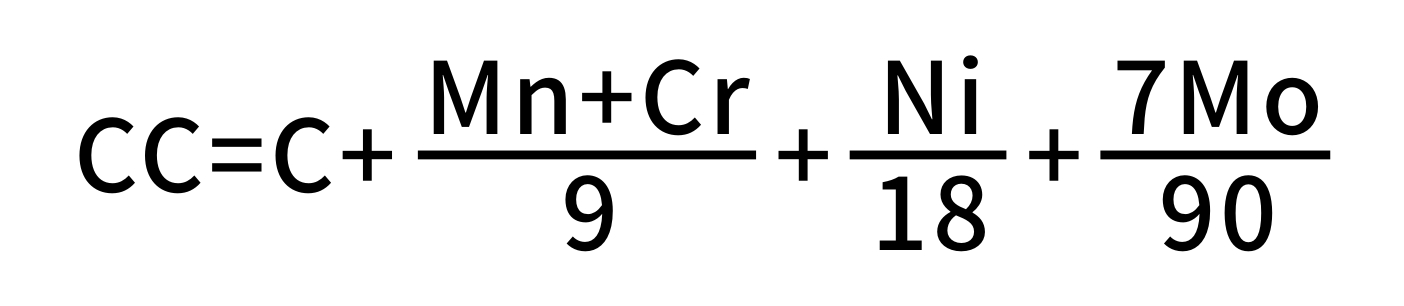

Ubale pakati pa zomwe zili mu kaboni ndi kutentha kwa preheating

Kuziziritsa pang'onopang'ono pambuyo powonekera ndi gawo lovuta kwambiri koma lomwe nthawi zambiri limanyalanyaza, makamaka pazopangira zazikulu. Nthawi zina zimakhala zovuta kukhala ndi zida zoyenera kuti muzitha kuzizirira pang'onopang'ono. Ngati palibe njira yothetsera vutoli, titha kulangizanso kuti tigwiritse ntchitonso Njira yogwiritsira ntchito magawo, kapena kupewa kuwotcherera pamene kutentha kuli kochepa, kuchepetsa chiopsezo cha ming'alu yozizira.

Zinayi. Mapeto

Palinso kusiyana kwa opanga payekhapayekha pazofunikira za hardfacing kwa ming'alu yogwira ntchito. Nkhaniyi imangokambirana movutikira potengera zomwe zidachitikazo. Gulu lathu lazinthu zolimba zapampando zowotcherera zolimba zimakhala ndi zinthu zomwe makasitomala angasankhe pazovuta zosiyanasiyana ndikugwiritsa ntchito. Takulandilani kukambilana ndi amalonda m'boma lililonse.

Kugwiritsa ntchito fakitale ya board yosamva kuvala

| Kanthu | Tetezani mpweya | kukula | Main | Mtengo wa HRC | Kugwiritsa |

| GFH-61-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Ndi: 0.6 Mn: 1.2 Mtundu: 28.0 | 61 | Oyenera mawilo akupera, zosakaniza simenti, bulldozers, etc. |

| GFH-65-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 22.5 Mo:3.2 V:1.1 W:1.3 Nd:3.5 | 65 | Oyenera kutentha kwambiri fumbi kuchotsa mafani masamba, kuphulika ng'anjo kudyetsa zipangizo, etc. |

| GFH-70-O | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 30.0 B:0.3 | 68 | Imagwira ntchito pa malasha odzigudubuza, ghost red, kulandira zida, chivundikiro cha malasha, chopukusira, etc. |

Kugwiritsa ntchito mumakampani a simenti

| Kanthu | Tetezani mpweya | kukula | Main | Mtengo wa HRC | Kugwiritsa |

| GFH-61-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Ndi: 0.6 Mn: 1.2 Mtundu: 28.0 | 61 | Oyenera kugaya miyala yodzigudubuza, zosakaniza simenti, etc |

| GFH-65-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 22.5 Mo:3.2 V:1.1 W:1.3 Nd:3.5 | 65 | Oyenera kutentha kwambiri fumbi kuchotsa mafani masamba, kuphulika ng'anjo kudyetsa zipangizo, etc. |

| GFH-70-O | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 30.0 B:0.3 | 68 | Oyenera akupera miyala odzigudubuza, mzukwa mano, kulandira mano, grinders, etc. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 Pa: 0.87 Mn: 2.6 Mo:0.53 | 36 | Itha kugwiritsidwa ntchito pazovala zachitsulo mpaka zitsulo monga mawilo a korona ndi ma axles |

| GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Ndi: 0.42 Mn: 2.1 Mtundu: 2.8 Mo:0.43 | 38 | Itha kugwiritsidwa ntchito pazovala zachitsulo mpaka zitsulo monga mawilo a korona ndi ma axles |

Ntchito ya Steel Plant

| Kanthu | Tetezani mpweya | kukula | Main | Mtengo wa HRC | Kugwiritsa |

| GFH-61-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Ndi: 0.6 Mn: 1.2 Mtundu: 28.0 | 61 | Oyenera kupaka ng'anjo ya ng'anjo ya zomera, mano a mizimu, mbale zosagwira ntchito, ndi zina zotero. |

| GFH-65-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 22.5 Mo:3.2 V:1.1 W:1.368 Nd:3.5 | 65 | |

| GFH-70-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Mtundu: 30.0 B:0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 Ndi: 0.65 Mn: 1.1 Mtundu: 13.2 | 52 | Oyenera kuponyera masikono, kutumiza masikono, masikono chiwongolero, etc. mu zomera mosalekeza kuponyera ndi otentha anagudubuzika zomera. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Ndi: 0.42 Mn: 1.1 Mtundu: 13.4 Mo:1.1 V:0.16 Nd:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C:0.25 Pa: 0.45 Mn: 2.0 Mtundu: 5.8 Mo:0.8 V:0.3 W: 0.6 | 51 | Anti-zomatira kuvala katundu, oyenera zitsulo mbale chiwongolero fakitale masikono, kutsina masikono ndi kuvala mbali pakati pa zitsulo. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C: 0.36 Ndi: 0.64 Mn: 2.0 Nd:2.9 Mtundu: 6.2 Mo:1.35 Mtundu: 0.49 | 52 |

Ntchito ya Miner

| Kanthu | Tetezani mpweya | kukula | Main | Mtengo wa HRC | Kugwiritsa |

| GFH-61-0 | Kudziteteza | 1.6 2.8 3.2 | C:5.0 Ndi: 0.6 Mn: 1.2 Mtundu: 28.0 | 61 | Itha kugwiritsidwa ntchito kwa ofukula, mitu yamsewu, ma picks, etc. |

| GFH-58 | CO2 | 1.6 2.4 | C: 0.5 Ndi: 0.5 nsi: 0.95 Nd:0.03 Mtundu: 5.8 Mo:0.6 | 58 | Oyenera kuwotcherera pamphepete mwa mbiya yoperekera miyala |

| GFH-45 | CO2 | 1.6 2.4 | C:2.2 Ndi: 1.7 Mn:0.9 Mtundu: 11.0 Mo:0.46 | 46 | Oyenera kuvala mbali pakati pa zitsulo |

Kugwiritsa ntchito vavu

| Kanthu | Tetezani mpweya | kukula | Main | Mtengo wa HRC | Kugwiritsa |

| GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn: 0.4 Pa: 0.1 Kr:13 Mo:0.01 | 40 | Oyenera kuwotcherera pamwamba pa ma valve osindikiza pamwamba |

| GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn: 0.4 Pa: 0.1 Kr:13 Mo:0.01 | 58 | Oyenera kuwotcherera ma valve okhala ndi corrosiveness kwambiri |

| GFH-D547Mo | Ndodo zamanja | 2.6 3.2 4.0 5.0 | C:0.05 Mn: 1.4 Ndi:5.2 P: 0.027 S:0.007 Nd:8.1 Mtundu: 16.1 Mo:3.8 Nd: 0.61 | 46 | Oyenera kutentha kwambiri, valavu yothamanga kwambiri yofikira kuwotcherera |

More information send to E-mail: export@welding-honest.com

Nthawi yotumiza: Dec-26-2022