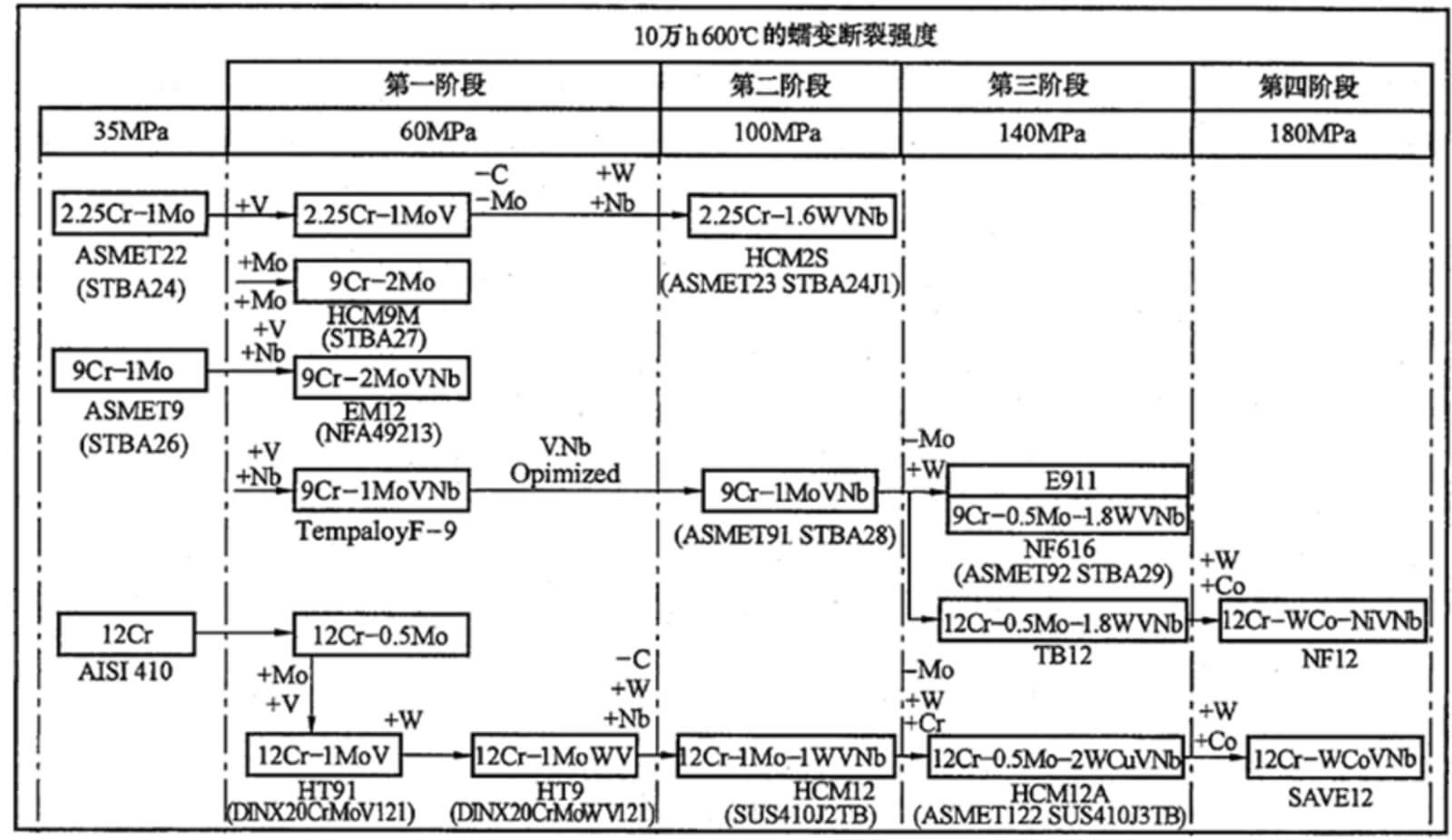

Kukula kwa chitsulo chosagwira kutentha kwa ferritic

Wonjezerani Cr-1.25Cr mpaka 12Cr

Onjezani V, Nb, Mo, W, Co, ndi zina.

Chitukuko cha chitsulo chosagwira kutentha kwa ferritic

Zindikirani:

Malinga ndi zochitika zapadziko lonse lapansi, zitsulo zotchedwa pearlite, bainite, ndi martensitic zosagwira kutentha muzitsulo zowotchera ndi mapaipi zimatchedwa "ferritic heat-resistant steels".

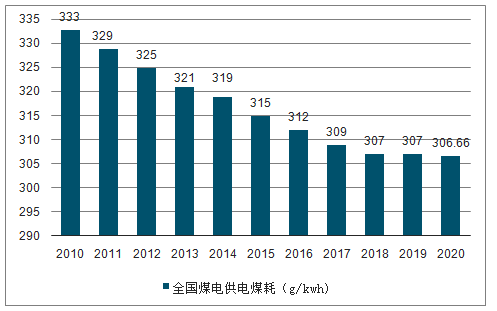

Ndi kusintha kwa dongosolo la mphamvu za dziko langa ndi kukhathamiritsa kwa zomangamanga zopangira magetsi, mphamvu zapamwamba, zoyera, komanso zachilengedwe zokhala ndi mphamvu zazikulu komanso zazikuluzikulu zakhala zazikulu. Powonjezera magawo a nthunzi (kupanikizika ndi kutentha), imatha kupititsa patsogolo kutentha kwa unit, kuchepetsa kugwiritsira ntchito malasha, ndi kuchepetsa mpweya wa CO2. Pakalipano, njira yayikulu yopititsira patsogolo mphamvu zamagetsi zamagetsi ndikuwongolera magawo a nthunzi ndikupanga mayunitsi apamwamba (SC) ndi ultra-supercritical (USC). Pakadali pano, m'dziko langa muli mayunitsi opitilira 100 miliyoni-kilowatt ultra-supercritical (USC) omwe akugwiritsidwa ntchito m'dziko langa, omwe ali oyamba padziko lonse lapansi mu kuchuluka komanso kuchuluka kwake.

Ziwerengero ndi Zoneneratu Zakugwiritsiridwa Ntchito Kwa Makala kwa Magetsi ku China kuyambira 2010 mpaka 2020

2.Main Chromium Molybdenum Steel Welding Rod Products

Table 2 Mawonekedwe a ma elekitirodi achitsulo oyimilira pearlitic

| Kanthu | Chofunikira chachikulu | Kutentha℃*H | Makhalidwe amakina | ||||

| Zotuluka Mpa | Tensile Mpa | Wonjezerani % | Kugwedezeka J/℃ | ||||

| GER-107 | 0.5% Mo | 620*1 | 477 | 570 | 24.0 | 152/0 | - |

| GER-207 | 0.5%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 143/0 | - |

| GER-307 | 1.25%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 146/0 | - |

| GER-317 | 1.25%Cr-0.5%Mo-V | 730*2 | 541 | 635 | 22.5 | 166/0 | - |

| GER-407 | 2.25%Cr-1%Mo | 690*1 | 586 | 682 | 21.0 | 142/0 | - |

| GER-417 | 2.25%Cr-1%Mo-V | 720*8 | 556 | 657 | 21.0 | 145/-18 | 120/-30 |

| GER-507 | 5%Cr-0.5%Mo | 740*1 | 490 | 605 | 23.0 | 124/0 | - |

Zindikirani:

1. Kampani yathu yapanga EXXXX-15, EXXXX-16, EXXXX-18 ndi ma slag ena opaka ma electrode amtundu womwewo kuti akwaniritse zofuna za msika. Zomwe zili pamwambapa zimangowonetsa magwiridwe antchito a ma elekitirodi a EXXXX-15.

3.2 Mndandanda wa maelekitirodi achitsulo osakanikirana ndi apamwamba kwambiri (ultra) ovuta kwambiri / martensitic

| ITEM | ZOYENERA | Khalidwe Lalikulu |

| GER-707 | AWS A5.5 E8015-B8 Mtengo wa GB/T5118 E6215-9C1M | 9% Cr-1% Mo Carbon steel core waya, kapangidwe ka aloyi yayikulu imasinthidwa kuchokera pakuyika, yoyenera mayunitsi amagetsi otenthetsera, A213-T9, A335-P9 zitsulo zowotcherera (zachuma komanso zogwira ntchito, zopanga bwino) |

| GER-91 Mtundu wa kore | AWS A5.5 E9015-B91 Mtengo wa GB/T5118 E6215-9C1MV | 9% Cr-1% Mo-Nb-vn Oyenera matenthedwe mphamvu mayunitsi zofunika, T/P 91 kuwotcherera zitsulo, waukulu aloyi zikuchokera anasamutsidwa pachimake kuwotcherera, mkulu kutentha microstructure ndi kukhazikika ntchito |

| GER-91M mankhwala khungu pachimake | 9% Cr-1% Mo-Nb-VN Oyenera matenthedwe mphamvu mayunitsi zofunika, T/P 91 kuwotcherera zitsulo, waukulu aloyi zikuchokera anasamutsa pakati kuwotcherera, mkulu kutentha microstructure ndi kukhazikika ntchito | |

| GER-92 Mtundu wa kore | AWS A5.5 E9015-B92 | 9% Cr-0.5% Mo-WV-Nb-N Oyenera matenthedwe mphamvu supercritical mayunitsi, T/P 92 zitsulo kuwotcherera, waukulu aloyi zikuchokera ndi kusintha kuchokera pachimake waya, mkulu kutentha microstructure ndi ntchito bata. |

| GER-93 | Muyezo wathu | 9%Cr-3%W-3%Co-Cu-V-Nb-B Ndizoyenera kuwotcherera zitsulo zapamwamba kwambiri za G115 zopangira mphamvu zamagetsi. Ili ndi dongosolo labwino komanso kukhazikika kwa magwiridwe antchito pa kutentha kwakukulu. Mphamvu yokhazikika ndi 1.5 nthawi ya P92 zitsulo, ndipo kukana kwake kutentha kwa kutentha kwa nthunzi ndi dzimbiri ndikwabwino kuposa P92 chitsulo. |

Mawonekedwe a Electrode

| Kanthu | Chofunikira chachikulu | Kutentha℃*H | Makhalidwe amakina | |||

| Zotuluka Mpa | Tensile Mpa | Wonjezerani % | Kugwedezeka J | |||

| GER-707 | 9%Cr-1%Mo | 740*1 | 540 | 670 | 24.0 | 119.7 |

| GER-91 | 9%Cr-1%Mo-Nb-VN | 760*2 | 557 | 702 | 21.0 | 96.3 |

| GER-91M | 9%Cr-1%Mo-Nb-VN | 760*2 | 553 | 701 | 22.5 | 81.0 |

| GER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760*2 | 596 | 706 | 21.5 | 103.0 |

| GER-93 | 9%Cr-3%W-3%Co | 770*4 | 580 | 720 | 20.0 | 77.7 |

Zindikirani:

1. GER-91M ndi ❖ kuyanika kusintha, ndiko kuti, kuwotcherera pachimake ndi wamba mpweya zitsulo pachimake waya, ndi aloyi waukulu amasinthidwa ndi ❖ kuyanika. Poyerekeza ndi GER-91 (mtundu wa kusintha kwa waya), ili ndi phindu labwino pazachuma ndipo ndi yapamwamba yathu Zopangira zazikulu zowotcherera zopangira mphamvu zotentha kwambiri.

3.Njira ya ASME ya 2015 imafuna E9015-B91 electrode Mn + Ni≤1.4%, ndipo mtundu wa 2017 umafuna ≤1.2% pazitsulo zoyambira. (mtundu waposachedwa wa 2021 wa ASME ukupitilizabe kugwiritsa ntchito mtundu wa 2015 wa zofunikira za ASME za ma elekitirodi a E9015-B91/ B92). Pofuna kukwaniritsa zofuna za msika, ndodo zathu zowotcherera za E9015-B91 ndi E9015-B92 zapanga mitundu iwiri ya zipangizo zowotcherera: Mn+Ni≤1.4% ndi Mn+Ni≤1.2%. Chifukwa chotsatiracho chili ndi zofuna zambiri zamsika, zomwe zili pamwambazi zikuwonetsa maelekitirodi 91/92 amayikidwa zitsulo Mn+Ni≤1.2%.

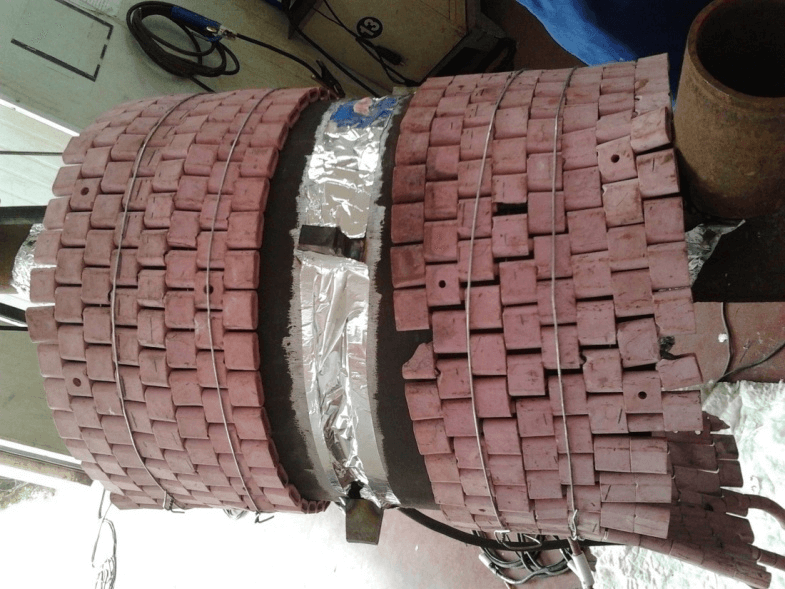

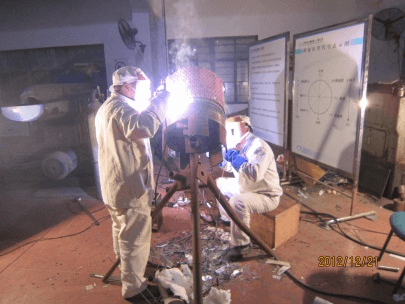

4. Chiwonetsero cha ndondomeko yowunikira ma electrode apamwamba kwambiri

4.1 Kuyenerera kwa ma welded P91/92

6. Ubwino ndi makhalidwe a maelekitirodi athu osagwira kutentha kwazitsulo za chrome-molybdenum

1. Pali mitundu yambiri ndi mitundu yonse

●Zolemba zake zimayambira 0.5%Mo mpaka 9%Cr-3%W-3%Co.

●Gwiritsani ntchito kutentha kuchokera pa 500 ℃ kufika pa 650 ℃.

● Mitundu yosiyanasiyana yokutira ndi zokutira (EXXXX-15, EXXXX-16, EXXXX-18) ingagwiritsidwe ntchito pazochitika zosiyanasiyana (mtundu wamba, mtundu wa mphamvu ya arc yamapaipi opangira magetsi).

● Ikhoza kukwaniritsa zofunikira zowotcherera zazitsulo zambiri za Cr-Mo.

2. Kuchita bwino

Zochita zabwino zamakina, magwiridwe antchito abwino kwambiri (kutsika kwa kutentha kwambiri komanso kukalamba kwakukulu).

3. Luso labwino

Electrode ili ndi manufacturability wabwino kwambiri m'malo onse, kuyaka kwa arc kokhazikika, kuuma kwabwino ndi mphamvu yowomba, sipatter yaying'ono, madzi abwino, mawonekedwe okongola a weld, ndikuchotsa mosavuta slag pambuyo kuwotcherera.

4. Makampani otsogolera

Anagwirizana ndi Suzhou Institute of Thermal Engineering, ndipo adapereka ndemanga ya "T / P 91/92 Localization Appraisal Meeting" mu 2015, ndipo adagwirizana ndi zigawo zazikulu zapakhomo monga Shenhua Guohua ndi General Iron ndi Steel Research Institute kuti apange 650 ° C. G115 chitsulo chothandizira zida zowotcherera ndi njira, ndikuchita misonkhano ingapo yosinthira zinthu zowotcherera.

More information send to E-mail: export@welding-honest.com

Nthawi yotumiza: Dec-27-2022