I. Mwachidule

Ndi chitukuko chofulumira cha kayendedwe ka mankhwala ndi mphamvu zapadziko lonse lapansi, akasinja osungira zitsulo zosapanga dzimbiri amagwiritsidwa ntchito kwambiri poyendetsa ndi kusunga mankhwala, chakudya ndi zakumwa, mphamvu ndi zipangizo zina. Chifukwa cha kulimba kwake kutentha kwambiri komanso kukana kwa dzimbiri, chitsulo chosapanga dzimbiri cha austenitic chimagwiritsidwa ntchito kwambiri pomanga akasinja osungira a cryogenic, zida ndi zida zazikulu za cryogenic.

Tanki yosungiramo cryogenic

2.Chidule chachidule cha -196 ℃ kutentha kutsika kukhudza zowotcherera zitsulo zosapanga dzimbiri

| Gulu | Dzina | Chitsanzo | Standard | Ndemanga | |

| GB/YB | AWS | ||||

| Electrode | Chithunzi cha GES-308LT | A002 | E308L-16 | E308L-16 | -196℃≥31J |

| Flux waya | Chithunzi cha GFS-308LT | - | Chithunzi cha TS308L-F C11 | E308LT1-1 | -196℃≥34J |

| Waya wolimba | Chithunzi cha GTS-308LT (TIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J |

| Chithunzi cha GMS-308LT (MIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J | |

| SAW | GWS-308/ GXS-300 | - | Chithunzi cha S F308L FB-S308L | ER308L | -196℃≥34J |

3.Ma elekitirodi athu GES-308LT (E308L-16)

Pofuna kukwaniritsa zomwe msika ukufunikira, kampani yathu yapanga mitundu yosiyanasiyana ya kutentha kotsika kwambiri, kulimba kwambiri kwazitsulo zosapanga dzimbiri za austenitic, maelekitirodi achitsulo chosapanga dzimbiri, kapangidwe kake kachitsulo komwe kamayikidwa (monga tawonetsera mu Gulu 1) ndi makina okhazikika (monga momwe tawonetsera mu Table. 2), ndipo ili ndi njira yabwino kwambiri yowotcherera pamawonekedwe onse, komanso kulimba kwa kutentha kochepa, mphamvu ya ferrite pamtengo wake (Table 3).

1.Chemical zikuchokera waika zitsulo

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 | 0.5-2.5 | 1.0 | 0.030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Chitsanzo1 | 0.022 | 1.57 | 0.62 | 0.015 | 0.006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Chitsanzo2 | 0.037 | 2.15 | 0.46 | 0.018 | 0.005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Chitsanzo3 | 0.032 | 1.37 | 0.49 | 0.017 | 0.007 | 11.79 | 18.66 | 0.021 | 0.027 | 0.048 | 0.6 |

Table 1

2.Mechanical katundu wa zitsulo zoyikidwa

| E308L-16 | Zotuluka MPa | Tensile MPa | Elongation % | -196℃kusintha J/℃ | GB/T4334-2020 E Intergranular dzimbiri | Rkuwunika kwa adiographic | Ndemanga | |

| Mtengo umodzi | Mtengo wapakati | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Chitsanzo1 | 451 | 576 | 42 | 32/32/33 | 32.3 | woyenerera | I | - |

| Chitsanzo2 | 436 | 563 | 44 | 39/41/39 | 39.7 | woyenerera | I | - |

| Chitsanzo3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | woyenerera | I | - |

Table 2

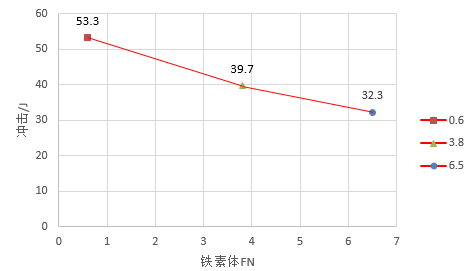

3.Zotsatira za kuchuluka kwa ferrite yachitsulo yomwe idayikidwa pazokhudza

4.Kuwonetsa njira yowotcherera (φ3.2mm)

Kuwotchera mowongoka musanayambe komanso pambuyo pochotsa slag (DC+)

Kuwotcherera mapaipi musanayambe ndi pambuyo pochotsa slag (DC+)

4. Kusamala kwa ofukula kuwotcherera

1. Kuwotcherera kwamakono kochepa kuyenera kugwiritsidwa ntchito;

2. Sungani arc yotsika momwe mungathere;

3. Pamene arc ikugwedezeka kumbali zonse ziwiri za groove, imani kwa kanthawi, ndipo m'lifupi kugwedezeka kumayendetsedwa mkati mwa 3 nthawi ziwiri za electrode.

5.Pipeline chithunzi cha kuwotcherera consumables ntchito

Pakuti -196 ℃ otsika kutentha zimakhudza zosapanga dzimbiri kuwotcherera consumables, patatha zaka kafukufuku ndi chitukuko cha consumables kuwotcherera, ife kale lolingana kuthandiza kuwotcherera consumables kwa ndodo kuwotcherera, mitima olimba, flux mitima ndi arcs kumizidwa, ndipo apanga dzanja electrode mosalekeza arc. kuwotcherera zinthu zowotcherera pazowotcherera malo onse, ndipo ali ndi zambiri zomwe akwaniritsa pakugwiritsa ntchito uinjiniya, alandileni makasitomala kuti mukambirane ndikusankha!

Nthawi yotumiza: Dec-16-2022