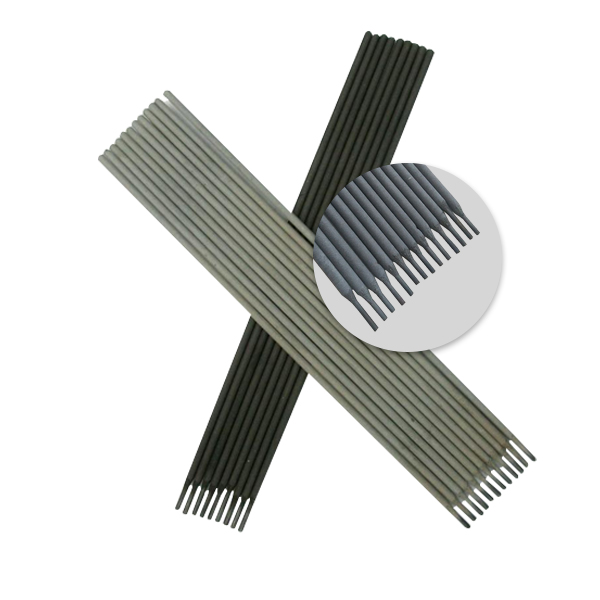

High Carbon steels Manual electrode E9818-G Soldering kupanga

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T MALAMULO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| MALAMULO AWS | - | - | - | - | - | - | - | - | - | - |

| CHITSANZO CHA VALUE | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||

| GB/T MALAMULO | - | - | - | - | - | |||||

| MALAMULO AWS | - | - | - | - | - | |||||

| CHITSANZO CHA VALUE | 915 | 992 | - | 65/-20 | 16 | |||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa wapamwamba mkulu mphamvu otsika ferrohydrogen ufa mtundu otsika aloyi zitsulo elekitirodi.

Khola lokhazikika, kuwaza pang'ono, kuchotsa bwino slag

Kuchita bwino kwambiri pamawotchi onse, kulimba kwa kutentha kochepa, kukana ming'alu komanso kulimba kwa kutentha kochepa.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T MALAMULO | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| MALAMULO AWS | - | - | - | - | - | - | - | - | - | - |

| CHITSANZO CHA VALUE | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||

| GB/T MALAMULO | - | - | - | - | - | |||||

| MALAMULO AWS | - | - | - | - | - | |||||

| CHITSANZO CHA VALUE | 915 | 992 | - | 65/-20 | 16 | |||||

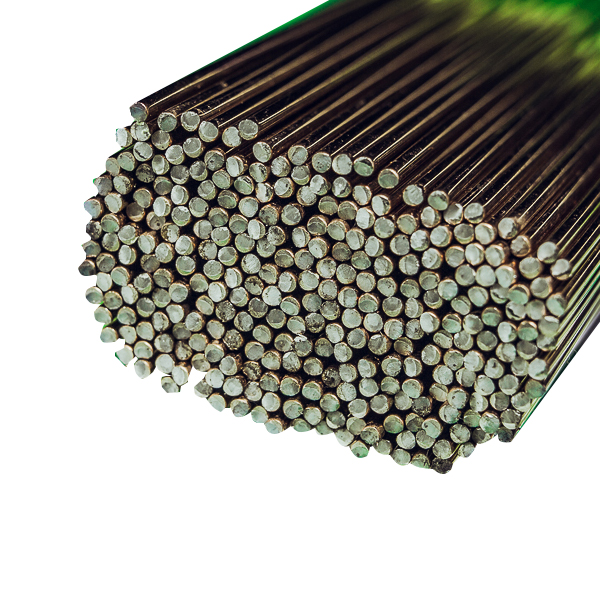

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Lembani uthenga wanu apa ndikutumiza kwa ife