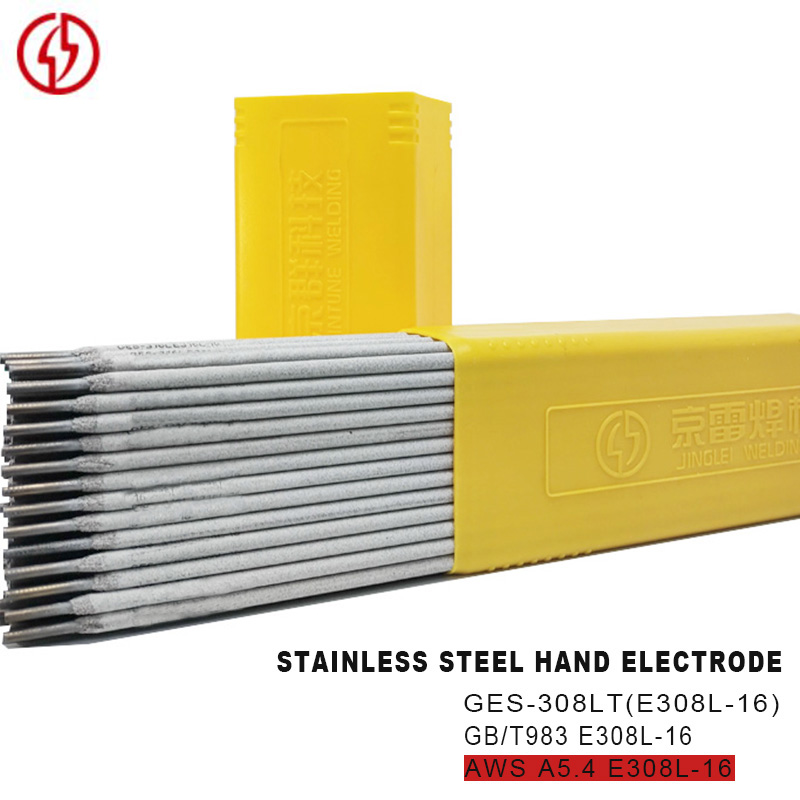

Zinthu zopangidwa ndi ma elekitirodi olimba a Manual

Ntchito & Standard

GEH-547 hardface wear-resisting hand electrode imagwiritsidwa ntchito kwambiri poyang'ana ndikukonza zida zamafuta ndi zida zosiyanasiyana zamakina. Monga zida za slag crusher zomwe zili pachiwopsezo (monga nyundo ya nyundo, mbale yowerengera), chipangizo chotsitsa simenti (thireyi, spire, kabati), makina opangira njerwa, makina osakaniza, makina obowola, fani yamagetsi opangira magetsi, kuphulika kwa zitsulo. ng'anjo chute akalowa mbale, wodzigudubuza, chulucho wosweka, makina makala ndi zina zotero. Kuwonekera kumatanthawuza kuuma, kukana kuvala ndi kukana kutentha kwa wosanjikiza wowotcherera, ndipo magwiridwe ake amagwirizana ndi izi:

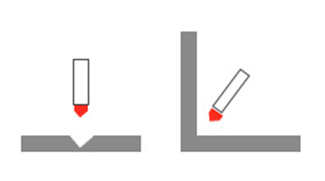

1. Kuwotcherera kukula, kutalika kwa arc. Large panopa, yaitali arc, alloying zinthu zosavuta kuwotcha, apo ayi, yabwino alloying zinthu kusintha. 2. Kutentha kwa preheating ndi kuzizira pang'onopang'ono kumatsimikizira mtundu wa wosanjikiza. 3. Njira zosiyanasiyana zochizira kutentha zingagwiritsidwe ntchito kupeza kuuma kosiyana kwa zitsulo zina zowonekera.

Mawonekedwe

GEH-547 ndi otsika sodium wa haidrojeni mtundu wa chromium-nickel butt kuwotcherera elekitirodi, ntchito yabwino, yocheperako kuwaza, yosavuta slag, yokongola mawonekedwe, yosavuta kuchita mawotchi; Kulimbitsa kwa silicon kumawonjezera kuuma, kukana abrasion, kukana kwa dzimbiri ndi kukana kwa okosijeni kwa chitsulo chowonekera. Vuto lodziwika bwino lomwe limakumana nalo poyang'ana pamwamba ndikung'amba. Njira zazikulu zopewera kusweka ndi izi: 1. Preheat pamaso kuwotcherera, kulamulira kutentha pakati pa zigawo, pang'onopang'ono kuzirala pambuyo kuwotcherera; 2. 2. Kutentha mankhwala kuthetsa nkhawa pambuyo kuwotcherera. 3, pewani ming'alu yamitundu ingapo, pogwiritsa ntchito ma elekitirodi otsika a haidrojeni. 4. Musanayambe kuwotcherera, iyenera kuumitsidwa pa 300-350 ℃ kwa ola limodzi; Ayenera kuchotsa m'munsi zinthu pamwamba chinyezi, dzimbiri madontho, mafuta, etc. Komanso ayenera kulabadira njira ya arc ndi arc.

Kampani & Fakitale

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T MALAMULO | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| MALAMULO AWS | - | - | - | - | - | - | - |

| CHITSANZO CHA VALUE | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| MPHAMVU (Ampa) | 80-120 | 120-160 | 160-210 | |||||

ZINTHU ZONSE

Zikalata

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | S |

| GB/T MALAMULO | 0.18 | 0.60-2.00 | 4.80-6.40 | 15.00-18.00 | 7.00-9.00 | 0.04 | 0.030 |

| MALAMULO AWS | - | - | - | - | - | - | - |

| CHITSANZO CHA VALUE | 0.05 | 1.26 | 5.34 | 16.8 | 7.78 | 0.028 | 0.006 |

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | |||||

| MPHAMVU (Ampa) | 80-120 | 120-160 | 160-210 | |||||