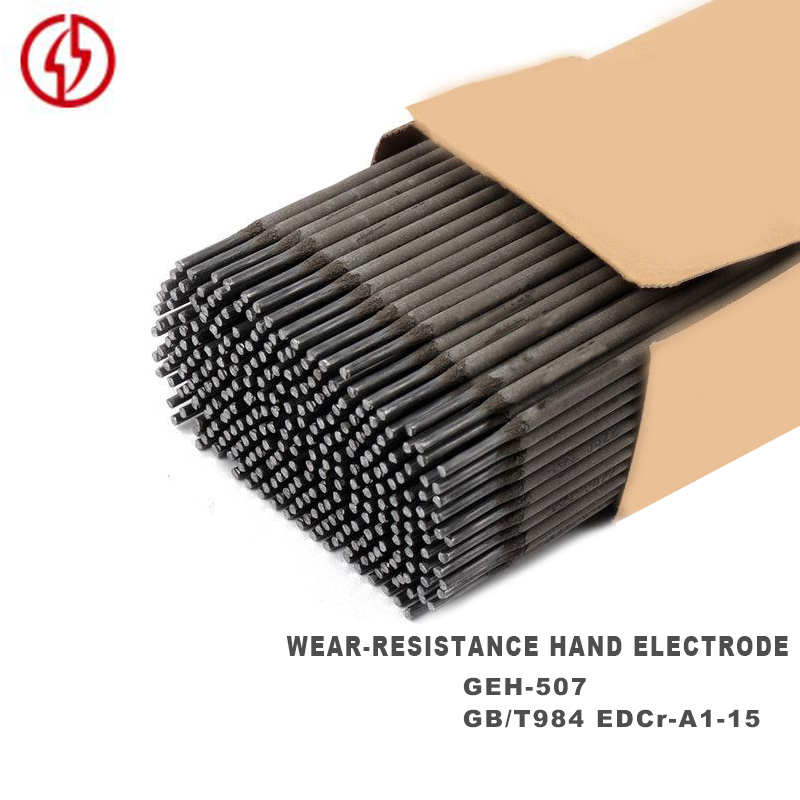

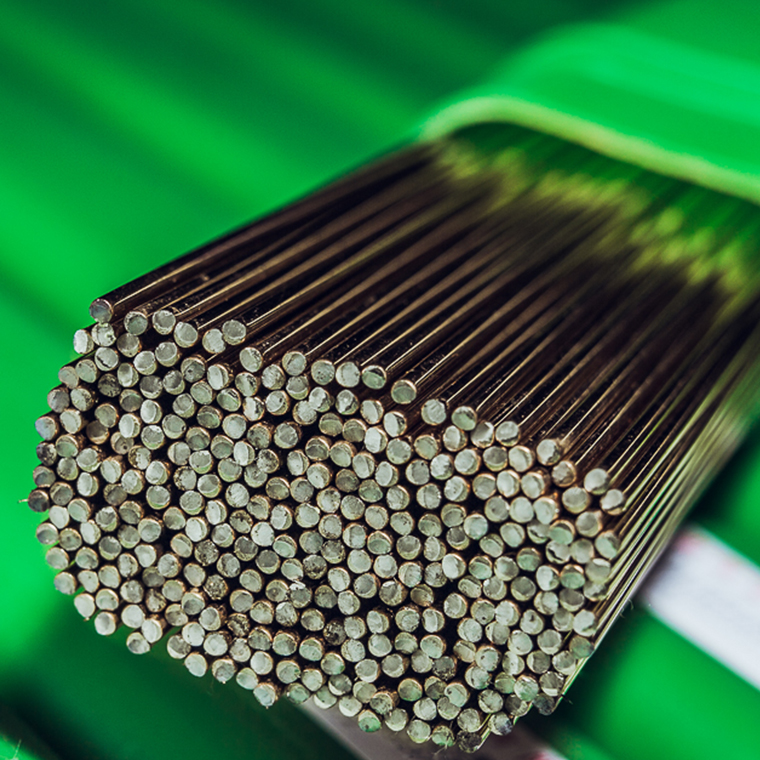

Cobalt alloys Manual elekitirodi ECoCr-A Welding zipangizo

Kugwiritsa ntchito

Amagwiritsidwa ntchito poyang'ana kutentha kwambiri ndi ma valve othamanga kwambiri, masamba ometa ubweya wotentha, ma valve a injini, masamba a turbine, ndi zina zambiri.

Zachilendo

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T MALAMULO | 0.70-1.40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Mphepete mwa nyanja |

| MALAMULO AWS | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Mphepete mwa nyanja |

| CHITSANZO CHA VALUE | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Mphepete mwa nyanja |

WELD PASS HARDNESS:

Mtengo wa chitsanzo HRC=46

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||

Titaniyamu-calcium yokutidwa cobalt-based electrode pamwamba ayenera kutengera DC reverse malumikizidwe.

Chitsulo chowoneka bwino chimatha kukhala ndi kukana kwamphamvu komanso kukana kwa dzimbiri pa 650 ℃, ndipo chimakhala ndi kukana kwamphamvu komanso kuzizira komanso kutopa kwa kutentha.

Itha kugwiritsidwa ntchito kuti ikhale yosasunthika bwino komanso kukana kwa dzimbiri pogwira ntchito pafupifupi 650 ℃, ndipo imatha kukhala ndi magwiridwe antchito abwino m'malo otentha komanso ozizira.

Onetsani zambiri

Anti- dzimbiri

Kukana kuvala

Zambiri zaife

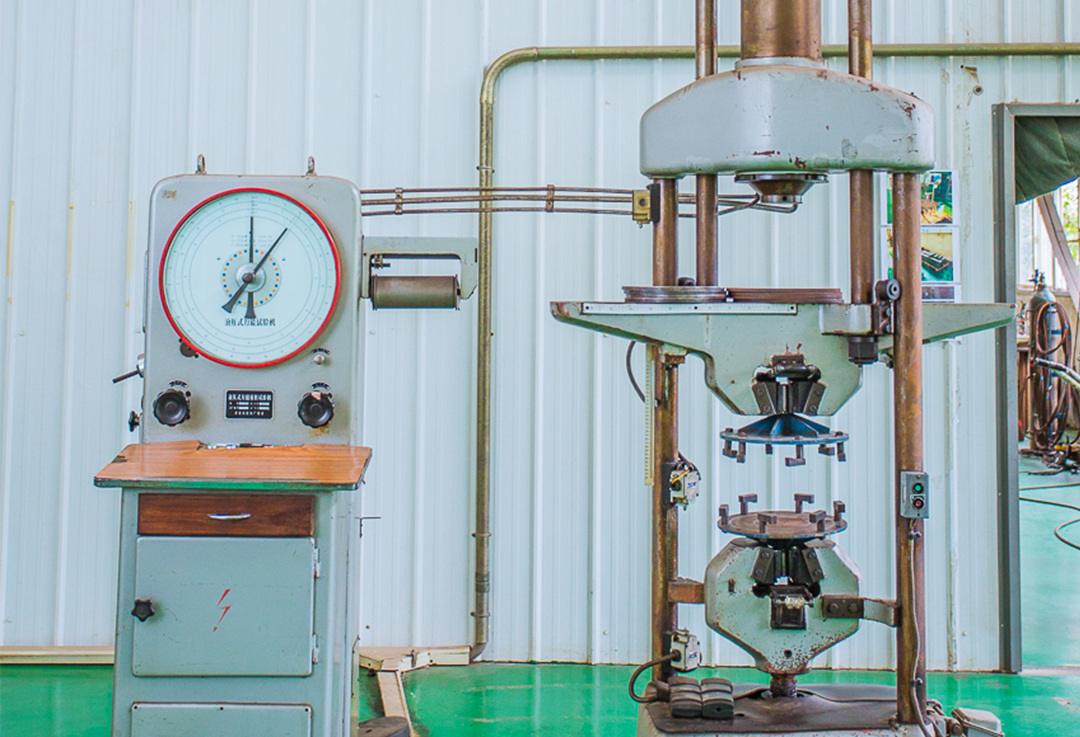

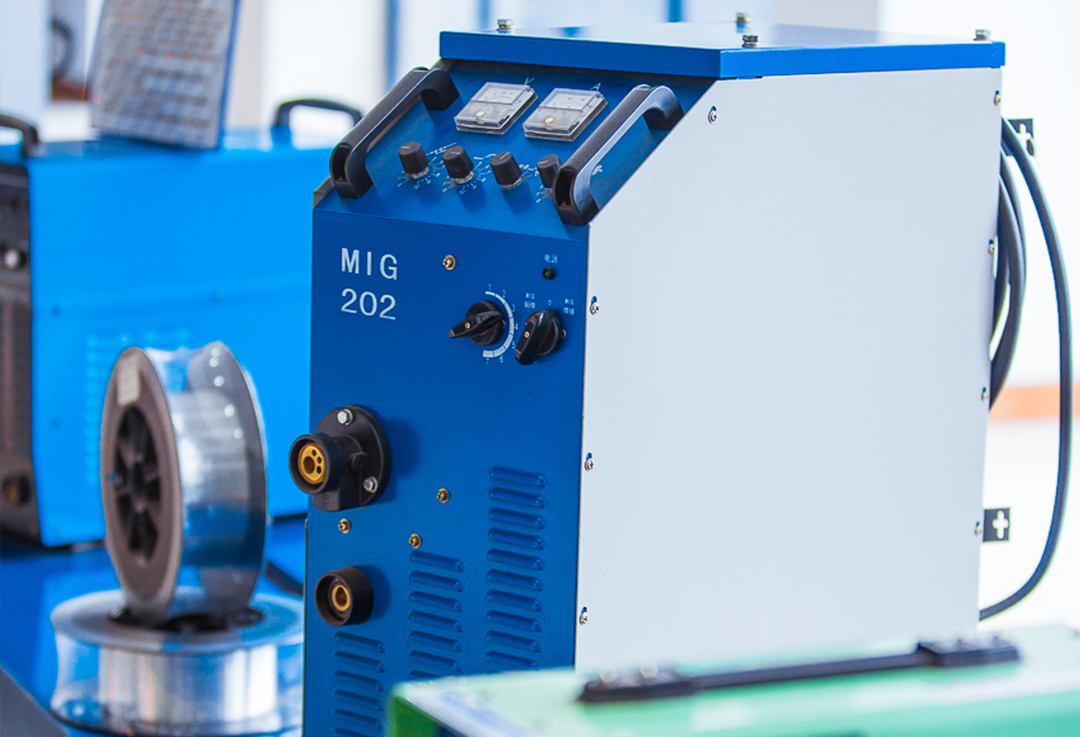

Chiwonetsero cha Factory Fioor

Mlandu wofunsira

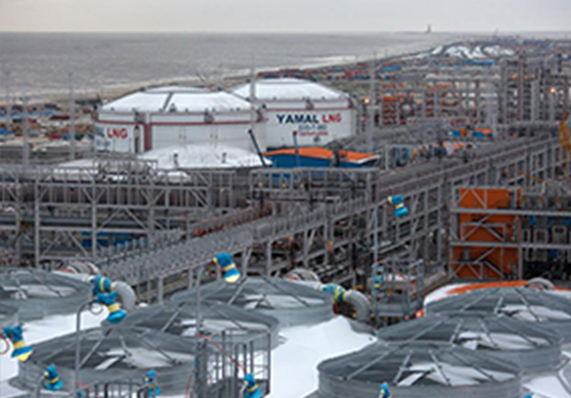

10 seti ya 4000m³ zitini zozungulira kuchokera ku Nanjing Jinling Petrochemical

Ntchito ya YAMAL LNG

Kuwombera kwafakitale kwenikweni

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | W | Co |

| GB/T MALAMULO | 0.70-1.40 | 2.00 | 2.00 | 25.00-32.00 | - | - | 5 | 3.00-6.00 | Mphepete mwa nyanja |

| MALAMULO AWS | 0.7-1.4 | 2.00 | 2.00 | 25-32 | 3.00 | 1.00 | 5.00 | 3.0-6.0 | Mphepete mwa nyanja |

| CHITSANZO CHA VALUE | 1.03 | 1.28 | 1.11 | 30.1 | 2.4 | 0.1 | 3.650 | 4.42 | Mphepete mwa nyanja |

WELD PASS HARDNESS

Mtengo wa chitsanzo HRC=46

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 3.2 * 350 | 4.0 * 350 | 5.0 * 350 | ||||||||

| ELECTRICITY(Amp) | 120-160 | 140-190 | 150-210 | ||||||||