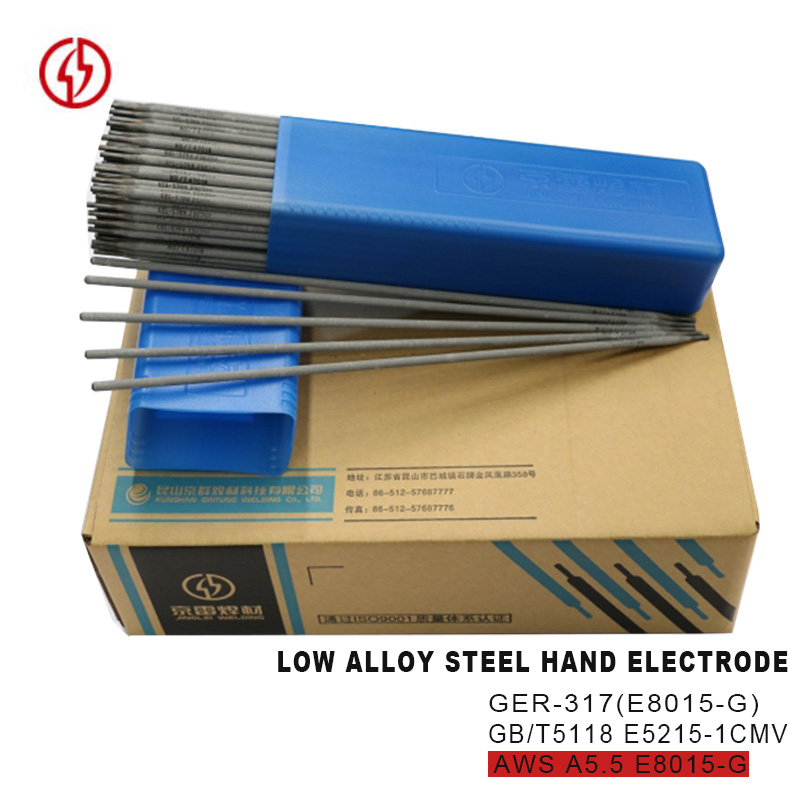

AWS E8015-G Low-alloy steels Solid Waya Welding Chalk

Ntchito&Standard&Zindikirani:

AWS E8015-G mtundu dzanja kuwotcherera elekitirodi kwa kutentha zosagwira zitsulo ndi oyenera kutentha ndi mkulu kuthamanga ng'anjo payipi ya siteshoni magetsi, kutentha kupanga makina mankhwala, zida zoyenga mafuta, etc. ndi kutentha ntchito m'munsimu 540 ℃, monga 12CrMoV. Ndipo angagwiritsidwenso ntchito kuwotcherera ntchito kutentha m'munsimu 540 ℃, monga 15CrMo pearlite kutentha kusamva zitsulo. Itha kugwiritsidwanso ntchito kuwotcherera zitsulo za 30CrMnSi. Zambiri mwazowotcherera zomwe zili ndi zofunikira zochepa za kaboni zitha kugwiritsidwa ntchito pamagetsi athu osagwira kutentha achitsulo. Imakhalanso yotchuka kwambiri pamsika, ndipo zotsatira za ndemanga zamsika zimakhalanso zabwino kwambiri. Timatengera luso lazopangapanga zapamwamba, kuwongolera mosamalitsa kaphatikizidwe kazinthu zopangira, kukonza ndi kupanga, kuyang'anira zinthu, ntchito yogulitsa pambuyo pa chilichonse, kupatsa makasitomala ma elekitirodi abwino kwambiri ndi waya.

Mawonekedwe

AWS E8015-G mtundu kuwotcherera elekitirodi pa kutentha zosagwira zitsulo ndi otsika sodium hydrogen mtundu dzanja kuwotcherera elekitirodi, ndi khola arc, pang'ono splash, bwino akamaumba, desagging mosavuta, kwambiri X-Ray ntchito, khola makina katundu, akhoza kukhalabe kulimba kwambiri pansi pa kutentha mankhwala. Elekitirodi yamanja iyi ndi pearlite kutentha kugonjetsedwa ndi chitsulo elekitirodi munali 0.5% molybdenum, 1% chromium, vanadium, ntchito DC m'mbuyo kuwotcherera ntchito, akhoza kukhala malo kuwotcherera, ayenera preheat kuti 250 ~ 300 ℃ pamaso kuwotcherera. Pambuyo kuwotcherera kutentha mankhwala ayenera kuchitidwa pa 730 ± 15 ℃ * 2h malinga ndi zofunika muyezo zipangizo kuwotcherera. Ndipo pamaso kuwotcherera, m`pofunika kuchotsa mafuta, dzimbiri, chinyezi ndi ntchito zina pa kuwotcherera.

Kampani & Fakitale

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T MALAMULO | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0.030 | 0.10-0.35 |

| MALAMULO AWS | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.20 | 0.04 | 0.030 | ≥0.10 |

| CHITSANZO CHA VALUE | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 460 | 550 | 730*2 | - | 15 | |||||||||

| MALAMULO AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| CHITSANZO CHA VALUE | 510 | 610 | 730*2 | 180 / Kutentha kwachilengedwe | 23 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| KUSINTHA | LENGTH | PCS/1KG | WIGHT/KG 1 | |||

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||

Milandu Yodziwika

Satifiketi

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S | V |

| GB/T MALAMULO | 0.05-0.12 | 0.90 | 0.60 | 0.80-1.50 | 0.40-0.65 | 0.03 | 0.030 | 0.10-0.35 |

| MALAMULO AWS | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.20 | 0.04 | 0.030 | ≥0.10 |

| CHITSANZO CHA VALUE | 0.07 | 0.75 | 0.35 | 1.15 | 0.5 | 0.013 | 0.018 | 0.150 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 460 | 550 | 730*2 | - | 15 | |||||||||

| MALAMULO AWS | 460 | 550 | 730*2 | - | 19 | |||||||||

| CHITSANZO CHA VALUE | 510 | 610 | 730*2 | 180 / Kutentha kwachilengedwe | 23 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| KUSINTHA | LENGTH | PCS/1KG | WIGHT/KG 1 | |||

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||