AWS E7018-A1 Zitsulo zotsika zachitsulo

Ntchito&Standard&Zindikirani:

AWS E7018-A1 (R106Fe) yosagwira chitsulo chosagwira magetsi pamanja ndi yoyenera kuwotcherera chitoliro cha boiler, chitoliro chotenthetsera kutentha pamwamba ndi chitoliro cha nthunzi pansi pa 450 ℃ (monga 15MoG, T1, P1 chitsulo) ndi zina. Monga machubu a ASTM A204 ndi A335-P1; The kuwotcherera ayenera preheated kwa 90-110 ℃ pamaso kuwotcherera, ndi kusunga kutentha interlayer. Angagwiritsidwenso ntchito kuwotcherera ambiri otsika aloyi zitsulo mkulu mphamvu zitsulo dongosolo. Ndipo elekitirodi dzanja angagwiritsidwe ntchito zonse udindo kuwotcherera. Malinga ndi makhalidwe a ndondomeko kupanga otsika kutentha liquefied mpweya, otsika kutentha zitsulo ntchito m'makalasi osiyanasiyana malinga ndi kutentha utumiki osiyanasiyana (-40 ℃, -70 ℃, -100 ℃, -194 ℃, -253 ℃ ), ndipo zida zowotcherera zofananira zimasankhidwa.

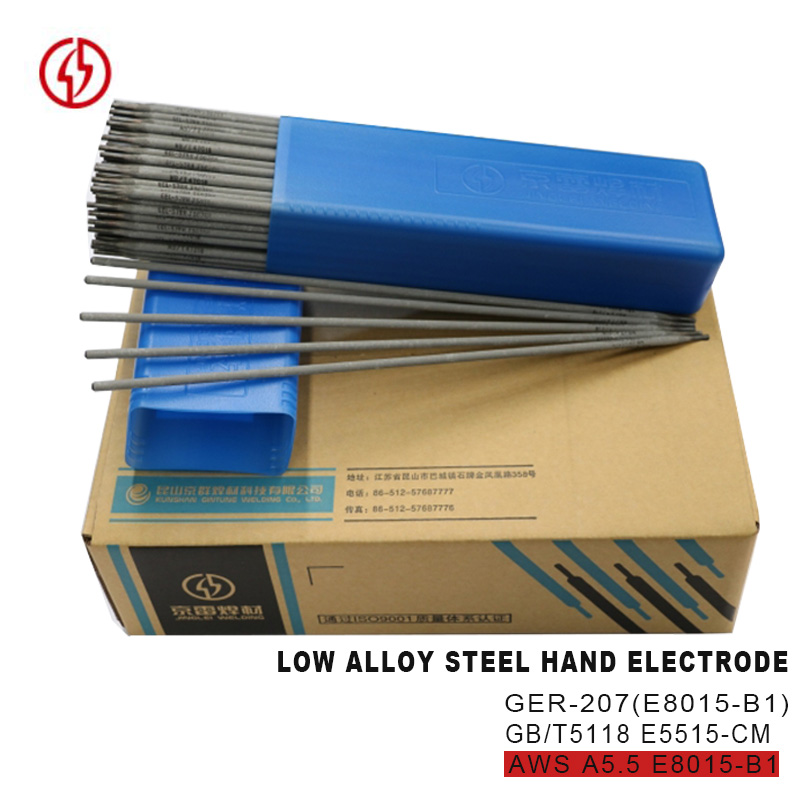

Mawonekedwe

Mtundu uwu wa elekitirodi dzanja ndi chitsulo ufa otsika haidrojeni mtundu dzanja elekitirodi, kuwonjezera chitsulo ufa, mkulu kusungunuka dzuwa; 0.5% Mo amawonjezeredwa kuti apititse patsogolo mphamvu zowotcherera komanso kukana dzimbiri; Ndipo arc ndi yokhazikika, yosasunthika pang'ono, kupanga, kuchotsa mosavuta, ntchito ya X-Ray ndi yabwino.

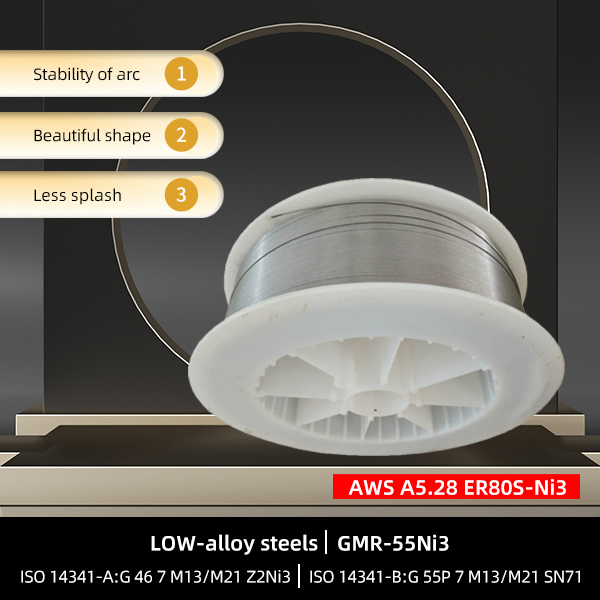

Zomwe zimagwiritsidwa ntchito popanga chitsulo chosamva kutentha kwa pearlitic ndi chromium, molybdenum, vanadium, niobium ndi zina zotero kuti zikwaniritse zofunikira zosiyanasiyana zogwirira ntchito. Chifukwa cha kuphatikizika kwa zinthu za carbon alloy muzitsulo, ndikosavuta kupanga mawonekedwe olimba panthawi yowotcherera, ndipo kuwotcherera kumakhala koyipa. Chifukwa chake, chitsulo chosamva kutentha kwa pearlitic nthawi zambiri chimatenthedwa chisanayambe kuwotcherera ndi kutenthedwa pambuyo pakuwotcherera.

Kampani & Fakitale

Kuyamba kwa mankhwala ndi makina katundu

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T MALAMULO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| MALAMULO AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| CHITSANZO CHA VALUE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 390 | 490 | 620*1 | - | 22 | |||||||||

| MALAMULO AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| CHITSANZO CHA VALUE | 480 | 570 | 620*1 | 170 / Kutentha kwabwino | 26 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| KUSINTHA | LENGTH | PCS/1KG | WIGHT/KG 1 | |||

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||

Milandu Yodziwika

Satifiketi

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T MALAMULO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| MALAMULO AWS | 0.12 | 0.90 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| CHITSANZO CHA VALUE | 0.6 | 0.7 | 0.31 | 0.035 | 0.5 | 0.012 | 0.01 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 390 | 490 | 620*1 | - | 22 | |||||||||

| MALAMULO AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| CHITSANZO CHA VALUE | 480 | 570 | 620*1 | 170 / Kutentha kwabwino | 26 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| KUSINTHA | LENGTH | PCS/1KG | WIGHT/KG 1 | |||

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||