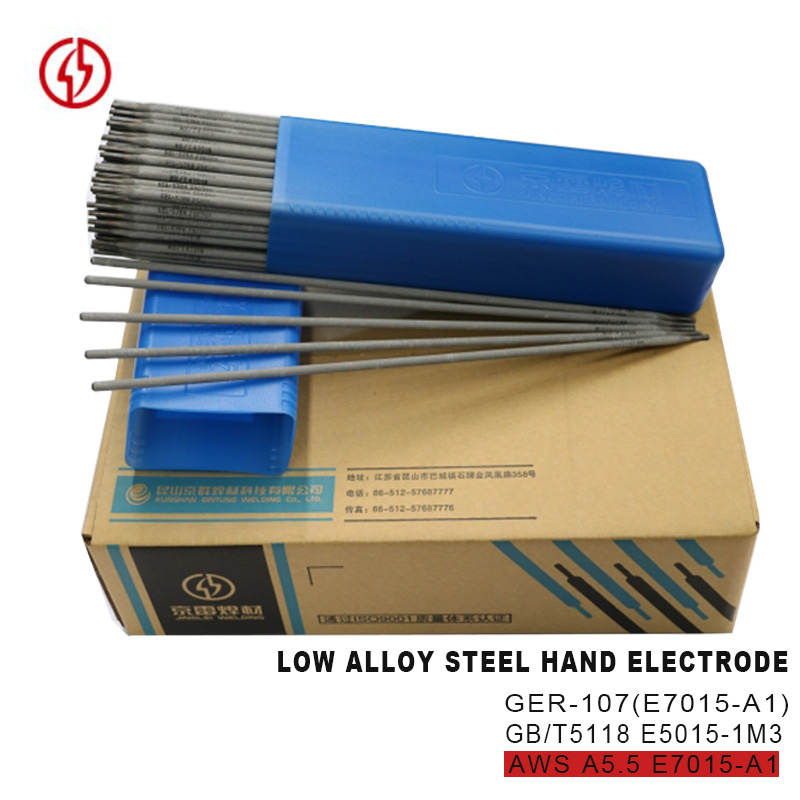

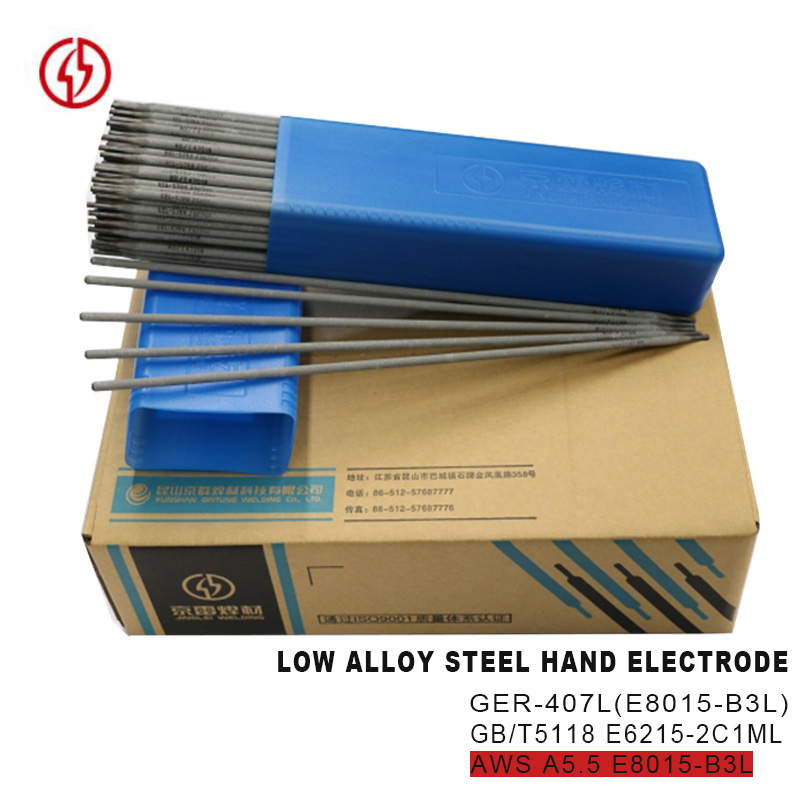

AWS E7015-A1 Zitsulo zotsika za alloy Manual electrode Welding accessories

Ntchito&Standard&Zindikirani:

E7015 mtundu otsika aloyi zitsulo dzanja elekitirodi ndi oyenera kuwotcherera ntchito kutentha m'munsimu 510 ℃ kukatentha chitoliro, exchanger kutentha ndi zina, monga ASTM A204 ndi A335-P1 chitoliro;

Elekitirodi iyenera kuumitsidwa musanagwiritse ntchito, sungani arc yaifupi, kugwiritsa ntchito njira yowotcherera yakumbuyo, kupewa kuchitika kwa porosity pa arc; Hydrojeni yochepa iyenera kusamalidwa panthawi yonse yowotcherera. Otsika aloyi zitsulo elekitirodi kusankha, kawirikawiri malinga zikuchokera zitsulo, katundu makina, kukana mng'alu ndi zofunika zina, komanso kuchokera kuwotcherera kapangidwe mawonekedwe, zikhalidwe ntchito, nkhawa ndi kuwotcherera zida ndi mbali zina za kulingalira mabuku. Ngati ndi kotheka, kuyezetsa ntchito kuwotcherera kudzachitika kuti adziwe ma elekitirodi ndi njira zoyenera ziyenera kutengedwa.

Mawonekedwe

1. Low sodium hydrogen electrode, kuwonjezera 0.5% Mo kupititsa patsogolo mphamvu zowotcherera ndi kukana dzimbiri;

2. Khola lokhazikika, kuwomba pang'ono, kupangika bwino, kosavuta kutsuka, X-Ray magwiridwe antchito ndiabwino kwambiri.

Nthawi zambiri kusankha elekitirodi lolingana ndi mphamvu ya kalasi zitsulo, pa nthawi yomweyo ayeneranso zitsulo weldability, kusintha kwa zigawo kholo zitsulo, angayerekeze kuyankha kapangidwe kukula, mawonekedwe, poyambira ndi maganizo ndende zinthu, monga mabuku. kuganizira, kuzirala liwiro kuwotcherera ndi lalikulu kwambiri, ndi mphamvu apamwamba, kuwotcherera zinthu mumsewu mosavuta osokoneza zinthu, nthawi zambiri akhoza kusankha zochepa kuposa mphamvu ya makolo zitsulo elekitirodi.

Kampani & Fakitale

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T MALAMULO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| MALAMULO AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| CHITSANZO CHA VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 390 | 490 | 620*1 | - | 22 | |||||||||

| MALAMULO AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| CHITSANZO CHA VALUE | 477 | 570 | 620*1 | 150 / Kutentha kwabwino | 28 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||

Milandu Yodziwika

Satifiketi

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Mo | P | S |

| GB/T MALAMULO | 0.12 | 1.00 | 0.80 | - | 0.40-0.65 | 0.03 | 0.030 |

| MALAMULO AWS | 0.12 | 0.90 | 0.60 | - | 0.40-0.65 | 0.03 | 0.030 |

| CHITSANZO CHA VALUE | 0.07 | 0.75 | 0.35 | 0.035 | 0.55 | 0.014 | 0.012 |

ZINTHU ZAMAKHALIDWE:

| THUPI | YOPHUNZIRA MPHAMVU (MPa) | KULIMBIKITSA MPHAMVU (MPa) | HEATTREAMENT℃xh | MFUNDO YA IMAPACT J/℃ | KULAMBIRA(%) | |||||||||

| GB/T MALAMULO | 390 | 490 | 620*1 | - | 22 | |||||||||

| MALAMULO AWS | 390 | 490 | 620*1 | - | 22 | |||||||||

| CHITSANZO CHA VALUE | 477 | 570 | 620*1 | 150 / Kutentha kwabwino | 28 | |||||||||

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 350 | 3.2 * 350 | 4.0 * 400 | 5.0 * 400 | ||||||

| MPHAMVU (Ampa) | H/W | 80-110 | 100-130 | 130-180 | 170-210 | |||||

| O/W | 60-100 | 80-120 | 120-160 | - | ||||||

ZINTHU ZONSE:

| 2.6 mm | 300 mm | 48PCS | 2KG pa | |||

| 3.2 mm | 350 mm | 27PCS | 5kg pa | |||

| 4.0 mm | 350 mm | 16 ma PCS | 5kg pa | |||

| 5.0 mm | 350 mm | 12 ma PCS | 5kg pa | |||