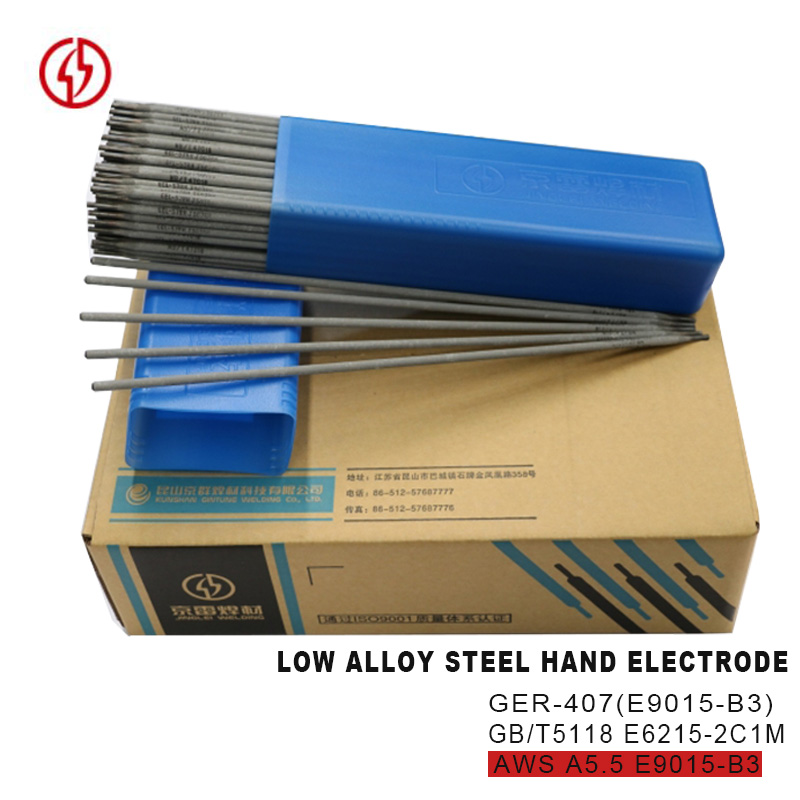

AWS A5.13 ENiCrFe-1 Nickel alloys Manual electrode Welding Chalk

Ntchito & Standard

ELECTRODE YA COBALT-BASED SURFACING ELECTRODE imeneyi INGAGWIRITSE NTCHITO PA CHIKOLERO CHA SHAFT SLEEVE, KUDULA M'mphepete KWA ZINTHU ZOPHUNZITSIDWA ZA CHEMICAL, SAWTOOTH, SCREW PUSH ROD, kutentha kwapamwamba ndi HIGH pressure valve ndi pampu yothamanga kwambiri ETC. Kuuma kwapamwamba kwa workpiece kuyenera kukhala kochepa kuposa Ra12.5μm, ndipo dzimbiri, mafuta ndi dothi lina ziyenera kuchotsedwa. Matrix sayenera kukhala ndi ming'alu, pores, mchenga ndi zolakwika zina, ndipo m'mphepete ndi m'makona ziyenera kukhala zozungulira. Asanakwere, kutentha kosiyana kuyenera kusankhidwa molingana ndi gawo lapansi la preheating. Pamene masanjidwewo ndi pearlitic chitsulo chosagwira kutentha kapena martensitic zitsulo zosapanga dzimbiri ndi zinthu zina zosagwira bwino ntchito kuwotcherera, austenitic wosanjikiza chitsulo chosapanga dzimbiri ayenera kuwotcherera pamwamba pa masanjidwewo, ndiyeno aloyi yochokera ku cobalt iyenera kuwonekera pambuyo pakukonza bwino. onjezerani kukana ming'alu ndikupewa ming'alu. Mphamvu zamagetsi zowotcherera za AC kapena DC arc zitha kugwiritsidwa ntchito pamagetsi a D802 ndi D812. Dc arc kuwotcherera magetsi akulimbikitsidwa.

Mawonekedwe

GEH-SL12 titanium calcium yokutidwa ndi cobalt-base electrode pamwamba. Cobalt-cr-tungsten alloy amagwiritsidwa ntchito ngati waya pachimake. Dc reverse connection ndiyofunika. Chitsulo chokwera chimatha kukhalabe ndi kukana kwamphamvu komanso kukana kwa dzimbiri pa 650 ℃. Musanayambe kuwotcherera, ziyenera kuphikidwa pa 300-350 ℃ kwa ola limodzi; Chosanjikiza chowumitsa pazitsulo zoyambira zitsulo ziyenera kuchotsedwa kuti zisawonongeke ming'alu ndi brittleness. Malinga ndi kukula kwa zitsulo zoyambira ndi mtundu wazitsulo zoyambira, ziyenera kutenthedwa pa 300-600 ℃, ndipo kuwotcherera kwa arc kwakanthawi kochepa ndikoyenera.

Kampani & Fakitale

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T MALAMULO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| MALAMULO AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| CHITSANZO CHA VALUE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | |||||

| MPHAMVU (Ampa) | Kuwotcherera kwathyathyathya/ kopingasa | 69-95 | 70-115 | 95-145 | ||||

| kuwotcherera molunjika / pamwamba | 55-80 | 65-110 | 80-130 | |||||

ZINTHU ZONSE

Zikalata

Kuyamba kwa mankhwala ndi makina katundu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | P | Fe | Nb+Ta | S |

| GB/T MALAMULO | 0.08 | 3.5 | 0.80 | 13.0-17.0 | ≥62 | 0.02 | 11.0 | 0.5-4.0 | 0.015 |

| MALAMULO AWS | 0.08 | 3.5 | 0.75 | 13.0-17.0 | ≥ | 0.03 | 11.0 | 1.5-4.0 | 0.015 |

| CHITSANZO CHA VALUE | 0.048 | 2.97 | 0.34 | 15.6 | 69.6 | 0.005 | 8.94 | 2.65 | 0.007 |

ZINTHU ZOWESETSA ZOMWE AMAKOKEZEDWA:

| ZINTHU ZA DIAMETERS(mm) | 2.6 * 300 | 3.2 * 350 | 4.0 * 350 | |||||

| MPHAMVU (Ampa) | Kuwotcherera kwathyathyathya/ kopingasa | 69-95 | 70-115 | 95-145 | ||||

| kuwotcherera molunjika / pamwamba | 55-80 | 65-110 | 80-130 | |||||